Using the correct equipment is just as critical as the planning itself. Depending on the task, this might include:

-

Full-body harnesses and lanyards

-

Fall arrest systems and anchor points

-

Ladders with safety feet and secure platforms

-

Guardrails and handrails for elevated areas

-

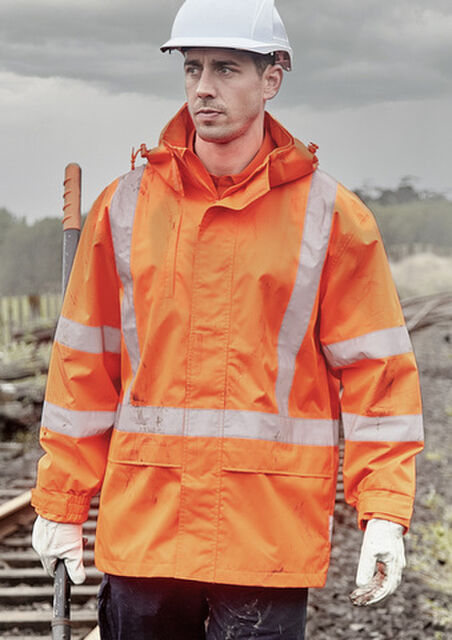

Personal protective equipment (PPE) like helmets and hi-vis gear

All equipment should meet relevant Australian Standards (like AS/NZS 1891 for fall arrest systems) and be regularly inspected for wear and compliance.